Automatic High Frequency Vacuum Wood Dryer

HF Vacuum Drying Machine is a relatively small and fast timber drying equipment. It adopts HF electric field as heating source, uniformly radiate to timber, directly heat moisture, speed up moisture removing by vacuum water absorption function, which is extremely suitable for solid wood and all kinds of timber processing factory, especially suitable for thick wood, hardwood, secondary drying (the first drying is incomplete and halfway),

quick drying and timber stress can be effectively eliminated and moisture can be balanced regardless of the wood internal, external and middle . So its suitable for beach and oak .

Case referance

–Final Moisture Content 8%-10% ( less than 3% of error )

Model Features

1. Vacuum Drying — 60℃ starting to vaporize , which can reduce wood cracking and deformation while achieving low temperature drying

2. Warp Deformation Recovering — Wood clamped by hydraulic system before drying, warping deformation to be recovered when soften , making output greatly improving and make easy palletizing

3. Quick Heating — No need heat conduction, inside and outside of wood timber are heated at the same time

4. Fast Dehydration— During the heating process, stepped temperature difference between inside and outside of wood can speed up the water movement from inside wood to outside wood

5. High Quality— Avoid outside & inside cracking and color change, by taking control of heating speed, relative vacuum degree and condensing rate.

6. Good Adaptability—It can achieve both low temperature and high temperature drying, also can eliminate stress , solidify resin and apply to dry almost all kinds of wood

7. Full-automatic & Easy operation -– Automatic feeding and discharging device , drying proceeding under unattended mode

8. Cost Saving — Low dry shrinkage and material saving

9. Sterilization function & Eco-friendly

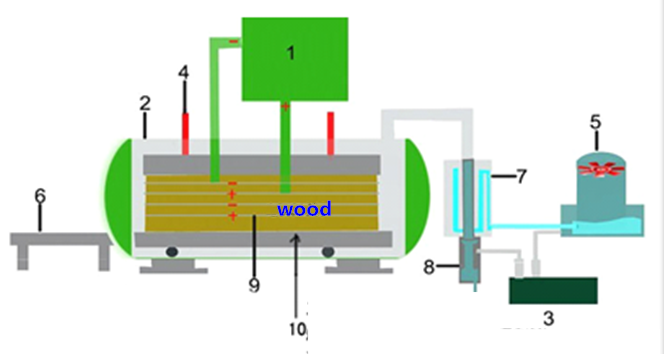

Structure

1. HF generator 5. Feeding track 6. Cooling tower 7. Cooling unit

2. Drying container 8. Vapor separator

3. Vacuum pump 9. HF heating electrode plate

4. Hydraulic pressure 10. Feeding device

Technique Data

| Model NO. | KC-3 | KC-4.5 |

KC-6 |

KC-8 |

KC-10 |

KC-12 |

|||

| Available Loading Size(mm) |

1000*1000*3000 |

1000*1000*4500 |

1000*1000*6000 |

1000*1000*8000 |

1300*1300*6000 |

1300*1300*8000 |

|||

| Inside Dia.(mm) |

1700 |

1900 |

|||||||

| Timber Capacity (CBM) |

3 cbm |

4.5 cbm |

6 cbm |

8 cbm |

10 cbm |

12 cbm |

|||

| HF Output Power |

30kW |

30kW |

60kW |

80 kW |

80 kW |

80kW |

|||

| Temperature Test |

Fiber Optic & digital temperature sensor |

||||||||

| Hydraulic Cylinder |

4T |

4T |

8T |

8T |

8T |

8T |

|||

| High Voltage Transformer | Dry-type transformer,built into HF machine cabinet |

Oil-immersed,separated cabinet |

|||||||

| Vacuum Pump Power | 5.5kW |

5.5kW |

7.5kW |

11 kW |

11 kW |

11kW |

|||

| Feeder Way |

Manual |

Automatic Feeder | |||||||

| Anticorrosion Inside |

Anticorrosion 304 stainless steel |

||||||||

| Piping |

Stainless steel mainly, parts of PPR |

||||||||

| Moisture Test |

Weighing System, electronic-weighing instruments |

||||||||

| Control System |

PLC |

||||||||

| HMI |

Touching HMI |

||||||||

| Steam Injection Pipeline |

Setting around |

||||||||

| Steam Generator |

Option |

||||||||

Model Features

—Vacuum Kiln is made of anti-corrosive 304 stainless steel , with strong pressure resistance and good sealing .

Good vacuum tank can lower the water boiling point , speed up the water movement in wood, and improve the drying speed, shorten the drying time.

—PLC and touch screen automatic control , easy and unattended operation during drying

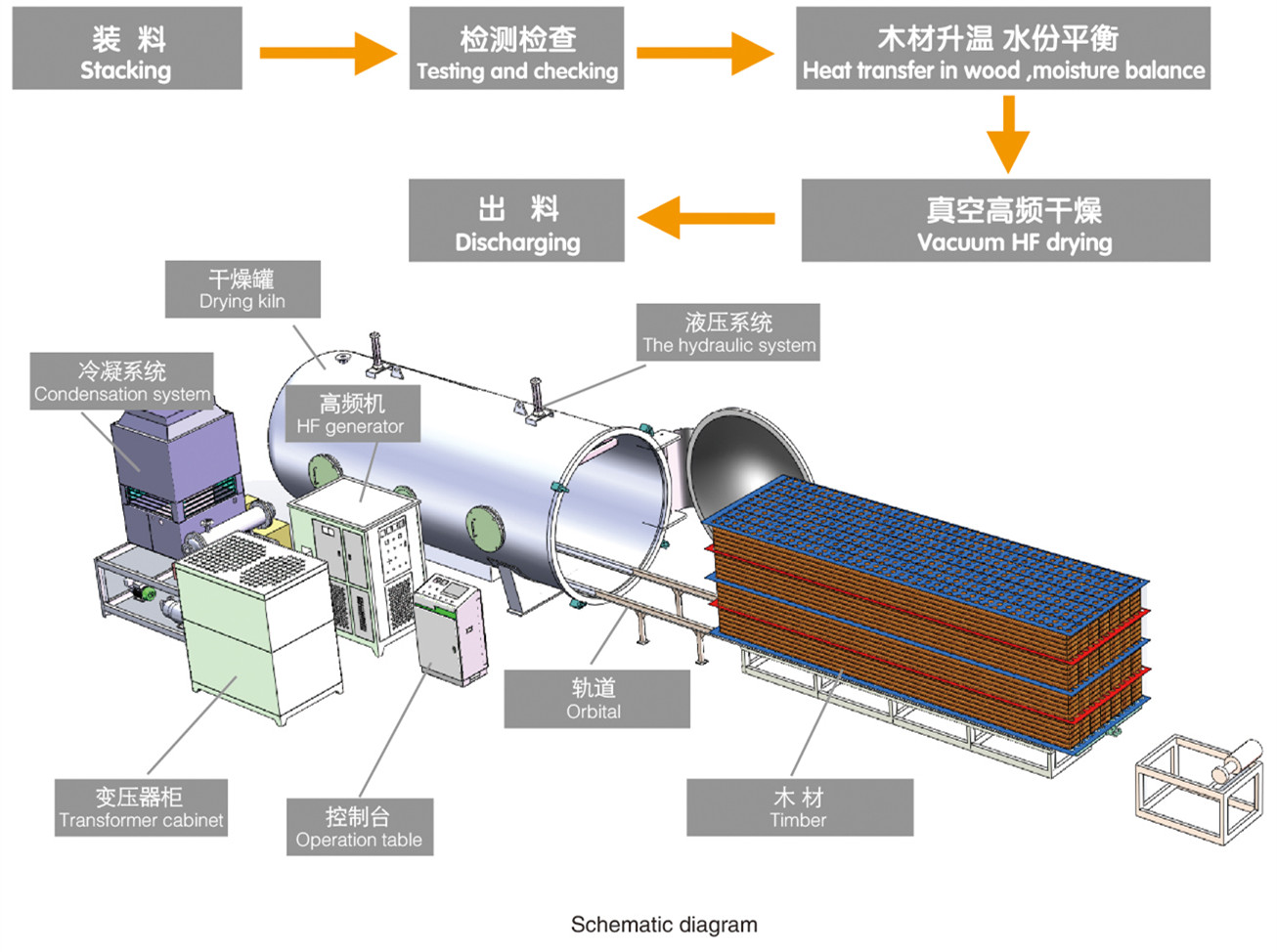

HF vacuum wood dryer Operation Process

Drying time for different timber

| Wood | Initial moisture content | Final moisture content | Drying time (hour) |

| Extremely-hard wood(within 50mm,above 50mm need 48h more) | |||

| Rosewood or valuable wood of density around 1.0 | 40% | 10% | Around 120 |

| 60% | 10% | Around 150 | |

| Mid-hard wood ( within 50mm,above 50mm need 48h more ) | |||

| Oak,ash,beech or wood of density around 0.6 | 20% | 8% | 70 |

| 40% | 8% | 120 | |

| softwood(within 100mm) | |||

| Pine or needle bush of density around 0.5 | 15% | 8% | 20 |

| 40% | 8% | 75 | |

20cbm HF vacuum wood dryer case

Contact us ! We will show you the difference between different Wood drying way , and which is the suitable one for you .

Operation Video