High Frequency Wooden Frame Assembling Machine

Our Patent Design

High Frequency Wooden Frame Assembling Machine , which is the most advanced wooden frame assembling machine in the world.

Application

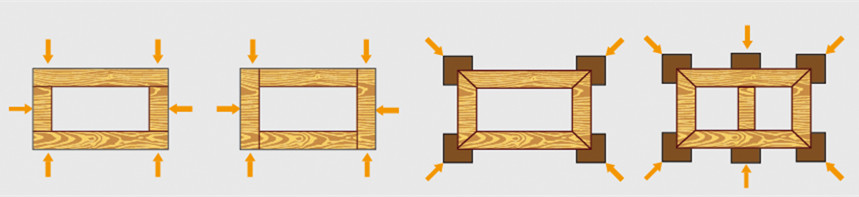

The machine is suitable for fast assembling of all kinds of wooden frame, with or without tenon, such as closet door, cabinet door, furniture frame assembly, drawer, mirror frame, and picture frame, which adopts high frequency power heating, four-angle pressurized mode.

Benefit

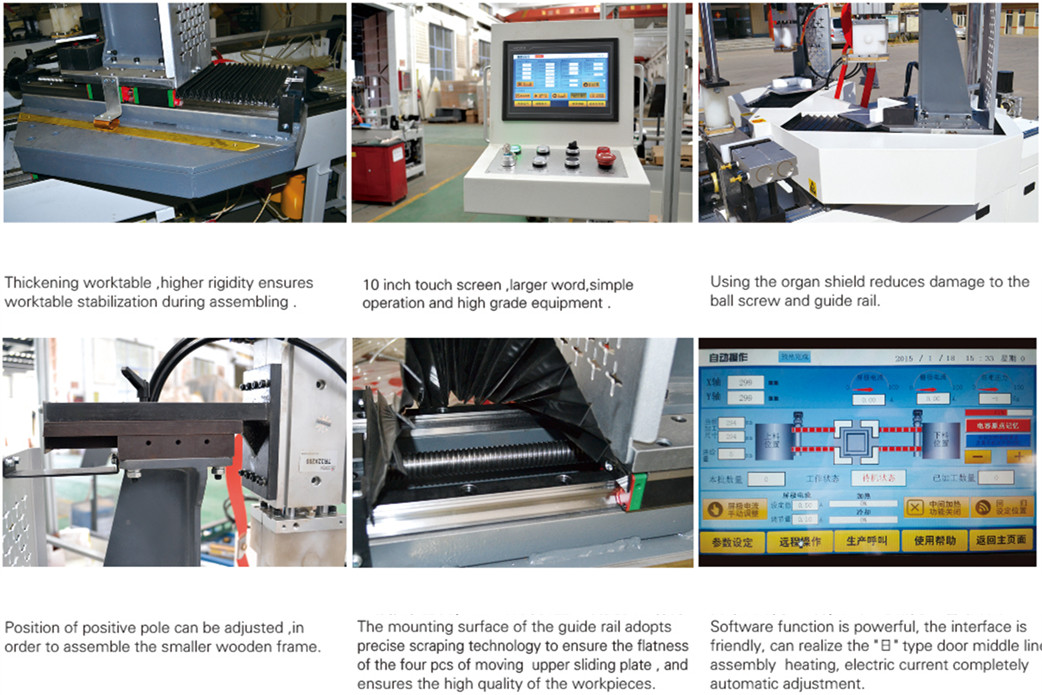

1. High speed : glue is solidified in 2-20 seconds, and it can operate on the assembly line .

2. Saving labor : it saves lots of time for loading and checking , and operate without fixtures

3. High quality: no need to use staple gun and improved subsequent procedures , the glue can be solidified under high pressure.

4. High precision: it adopts the ball screw and precision linear guide, and controls the machine with motor, diagonal error minimization

5. Low cost: a frame only costs about 0.003-0.04KWh

6. Convenience: it adopts touch screen of human-machine interface, easy change the dimension automatically , PLC automatically control, all data can display on touch screen, including pressure, current, heating time and cooling time, etc

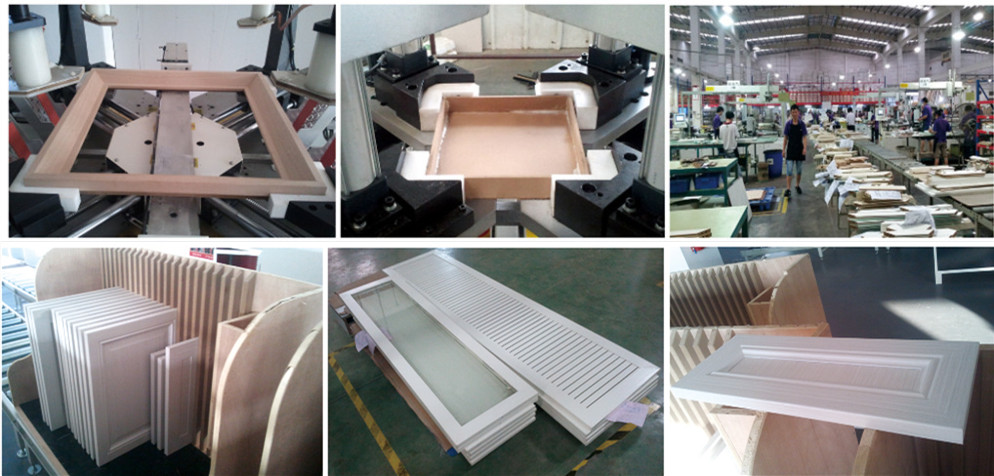

Referance Case

Parameter

| Model No. | KC-1200X800 | KC-2000X800 | KC-2800X800 | KC-2800×1000 | KC-3400X1200 |

| Max. working size(mm) | 1200×800 | 2000×800 | 2800×800 | 2800×1000 | 3400×1200 |

| Min. working size(mm) | 80×80 | 130×130 | 130×130 | 130×130 | 200×200 |

| Pressing way | precision lead screw | ||||

| Overall size(LxWxH)(mm) | 2000x1180x1750 | 2760x1180x1750 | 3560x1180x1750 | 3560x1380x1750 | 4160x1580x1750 |

| Weight | 800kg | 1500kg | 2000kg | 2200kg | 2500kg |

Model Details

Workshop

Operation Video