Vertical Fully Automatic Finger Joint System

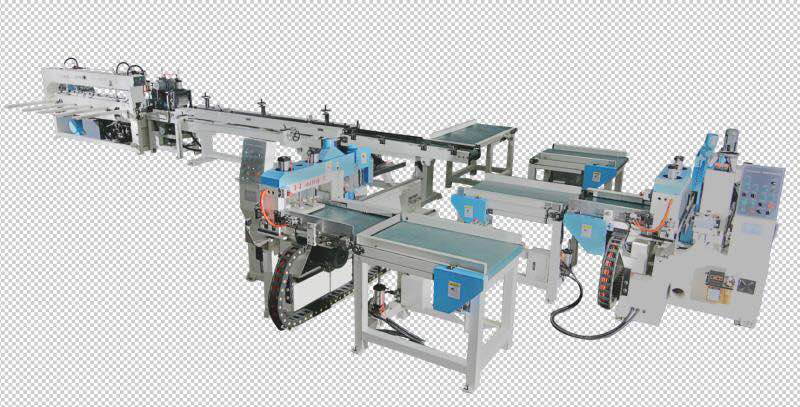

VERTICAL FULLY AUTOMATIC FINGER JOINT SYSTEM (BELT TYPE)

(standard : with variable frequencey motor)

All From Taiwan

Application

Finger jointing is recognized as the most stable method of creating length joints between two solid wood or wooden composite components. It is used in order to produce very long wood components or to separate out knots and cracks which lower the strength. Using finger joints it is possible to joint short pieces of wood into one, in principle, infinitely long strand of wood.

Our finger jointing line, offers a particularly workable solution for length joints processing for both vertical and horizontal finger joints ,with belt conveyor, finger joint shaper (with glue), roller conveyor, chain conveyor, using extremely user-friendly , easy-operated, noise-free system to achieve high precision effect.

Component :

Feeding table + H-600F3 shaper + H-600F4 shaper with gluing + Middle feeding table

+ Middle auto chain feeder + H-6015CFP press

HMI system controled + PLC controled

A. H-600F3 Automatic finger joint shaper

(Bottom scoring saw + Conveyor +Cut-off saw +Spindle shaper)

Working table width: 610mm

Working length: 150-900mm

Working thickness: 18-150mm

Speed of cut-off saw: 2900rpm

Speed of scoring saw: 2840rpm

Speed of spindle shaper: 6750rpm

Spindle shaper motor: 20HP

Cut-off saw motor: 7.5HP

Hydraulic motor: 5HP

Scoring saw motor: 2HP

Conveyor motor: 1/2 HP,1:5

Chip outlet hood: D100mm×4pcs

Machine size: 3200×1700×1400mm

B. H-600F4 Automatic finger joint shaper

(Top/Bottom scoring saw +Conveyor+ Cut-off saw + Spindle shaper + Auto gluing )

Working table width: 610mm

Working length: 150-900mm

Working thickness: 18-150mm

Speed of cut-off saw: 2900rpm

Speed of scoring saw: 2840rpm

Speed of spindle shaper: 6750rpm

Spindle shaper motor: 20HP

Cut-off saw motor: 7.5HP

Hydraulic motor: 3HP

Scoring saw motor: 2HP×2pcs

Conveyor motor :1/2 HP

Chip outlet hood: D100mm×4pcs

Machine size: 3800×1700×1500mm

C. Conveyor table

Table size: 600mm X 1000mm X 3pcs

Conveyor motor: 1 HP×3pcs

D. Middle conveyor table

Conveyor motor: 1HP

Table size: 600mm×1600mm

E. Toss table

Table size: 900mm×1600mm

Conveyor motor: 1 HP

Toss conveyor motor: 1HP

F. Middle auto chain conveyor

Table size: 600mm×5000mm

Motor: 1/2HP×2pcs

Chain specifications: 10A

G. Plastic table (Double idler wheel)

Retarder motor: 1/2HP, 1/5HP(with brake )×2pcs

Table size: 450×100mm

H. H-6015CFP automatic finger joint Hydraulic press

(Conveyor belt + Air pressure wheel ×2pcs)

Working length: 6000mm

Working width: 22-150mm

Working thickness: 18-75mm

Working speed: 8-80m/Min

Speed of cut-off saw: 2840rpm

Air pressure: 6kgs/cm2

Max. hydraulic pressure: 70kgs/cm2

Cut-off saw motor: 3HP

Hydraulic motor: 5HP

Feeding motor: 1/2HP

Machine size: 6800×1000×1700mm

Model Details

What make ours different ?

1. High efficient: can finish 5-6pcs x 6m wood per min for full-auto ones, 16-20pcs x 2.5m wood per min for semi-auto ones

2. Heavy duty : new weight reach to 11 tons for 6m full-auto ones, 9 tons for 2.5m semi-auto ones

3. Using Taiwan electrical control components and technology to ensure efficient , high performance and stable operation.

4. Using Servo motor drive, fast returning speed, 1.3 seconds positioning, good stability (optional)

5.The shapers adopt intelligent detection device to ensure all work piece are on the same plane before shaping

6. Adding a special device on the shaper to adjust the working speed , preventing the last work piece be cracking

7.Adding a conveyor between two shapers , to ensure all work piece are on the same plane before shaping, which also can fasten working speed

8. HMI system control ,which displaying operation, fault and maintenance information, easy operation

9. Following CE standard and user-friendly features to make more stable and reliable, assuring a world quality.

10.Accommodating different wood size requirement and multiple levels of wood moisture and hardness.

Series Models

High Speed Full Automatic Finger Joint Line (with cover)

Semi-automatic Finger Joint Line

Operation Video