KC-1 Small Sander

Application

The Mini sanding machine mainly apply for profiled milling, polishing, fine sanding of special-curved or standard blank and lacquer work pieces,like laminated lumber,chipboard,composite board, particle board,solid wood floor,panel furniture,bamboo floor,wood door and window ,cabinet,arts and crafts, WPC, and plank stuff for furniture etc.

1. Safety Protection : Schneider appliances can assure the machine with good performance under safety working voltage

2. Heavy-duty Frame : Cast steel girder , base and front plate to strengthen the stability of machine , and improve sanding performance

3. Frequency converter control : Schneider Electrical Frequency converter controls rotational speed as well as abrasive belt feeding , to ensure working perfectly and effectively

4. Flexibility : Sanding belt and compound mode with different sanding discs and rollers are optional according to different work pieces

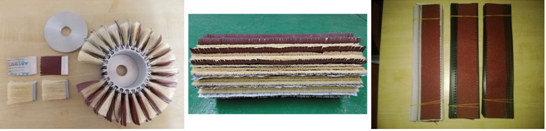

5. Easy replaced brush : The brush is made of special sisal and abrasive sheet, easy to be replaced separately to lower cost

Sanding Material

–Sisal made of hard fiber .with anti-static and strong wear resistance

–POM gear ,made of engineering plastic with better rigidity, heat-resistance, distortion-free

Parameter

|

Model |

KC-1 |

|

Max Working size |

150mm |

|

Power |

1.5kw |

|

Sanding Roller Speed |

0-700r/min |

|

Roller Diameter |

Ø190mm |

|

Sanding Head Diameter |

Ø280mm |

|

Dusting Outlet Diameter |

Ø 125×1 |

|

Weight |

170KG |

|

Voltage |

380V/50HZ |

|

Model Size |

750x750x1250 mm |

Service Industry

Providing a full range of sanding material with 20000m2 factory , serving for industry of furniture, flooring, musical instrument, sound box, stainless steel , metals fittings , aluminum, leather etc.

Why us ?

Capacity improving by 5 times

Only 33% of sanding space is needed

Only 25% of sanding workers

Only 50% sanding belt wastage

One-stop shop to solve sanding problems