Heavy Duty Planer Sander

Application

Integrated planer with sander, this machine has high efficiency in the procedure of thickness fixing and precise sanding. It is suitable for sanding rough surface boards and glued boards such as jointed panel boards, block boards and so on.

Our design of anti-vibration and firmness solve the problems caused by high speed planer shocking on the board. 174pcs German carbide knives divided into 6 lines are along the planer spirally, which guarantees the plane quality and efficiency.

Model details

1. Rational structure design

2. Planer roller

—174pcs German carbide knives.

—6 lines along the axial planer spirally

3. Combination pf segmented press board and single press roller

—Stop the board kickback

4. Bearing

—SKF bearing

—Higher precision

—Easy maintenance

5. Conveyor table surface

—Mirror finishing

—Flatness within 0.05mm

—Heat treatment by high temperature

6. PLC

—-Brand DELTA

—-Widely used in all electric controller

7. Photo eye

—BANNER imported from American

—Super penetrability

8. Electric components

—-TECO brand from Taiwan

—-Quality guarantee

9. Gearbox

—High quality gearbox with inverter motor

10. Mechanical welding

—Automatic welding by mechanical hand

—Heat treatment

—Thick Rectangular steel pipe

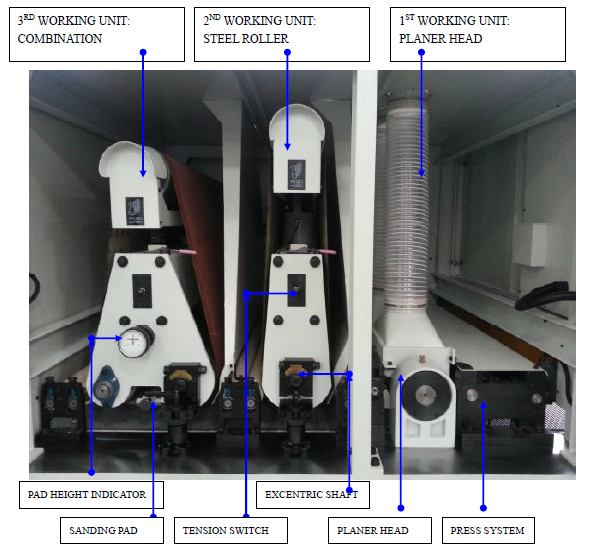

Internal Display

Model Features

1. Suitable for sanding rough surface boards and glued boards such as jointed panel boards, block boards and so on.

2. Carbide knife+stell roller+combination working unit work together to sand and plane in a high efficiency.

3.The planer head assembles 174pcs German carbide knives,which spiral 6 lines along the planer head.The carbide knife with small spiral angle and arc shape blade ensure the quality and efficiency.

4. The combination of double press rollers and three segmented press board ensures stability and safety during the plane. Front anti-kickback fingers stop board back immediately.

5. Rollers are tested by dynamic balance machine, which can improve precision and avoid S-shaped grain.

6. Conveyor bed is processed by mirror finishing, leading to a high flatness. The material remains stable and high precision after heat treatment.

7.Sander frame adopts high quality steel, which keeps stable and no deformation by heat treatment. It reduces vibration when running and ensures the sanding precision.

Parameter

Model No.: BSG1000K-R-RP Planer sanding machine

| 1) Processed data | Working width: 50-1000mm | Working thickness:10-150mm | Min.working length: 440mm |

| 2) Sanding roller diameter | Planer rollerφ190mm | First roller φ180mm | |

| 3) Running speed | Conveyor belt: 0-19m/min(inverter) | First roller: 21m/s | Second roller: 17m/s |

| Planer roller 27.5m/s | |||

| 4) Size of belt | Sanding belt: 1030x2200mm | Conveyor belt: 1000x4640mm | |

| 5) Motor power | Total motor power: 51.62kw | ||

| First belt motor: 15kw | Second belt motor: 11kw | Planer roller:22kw | |

| Feeding motor: 3kw | Lifting motor: 0.37kw | Brush motor: 0.25kw | |

| 6) Size | Overall size: 2723*1653*2052mm | ||

| 7) Weight | About 3860kg | ||

| 8) Others | Working pressure: 0.4-0.8Mpa | Compressed air consumption: 1.5m³/min | Average speed of sucked air 25-30m/s |

Package

Operation Video