Newly High Frequency Wood Board Press (full cover)

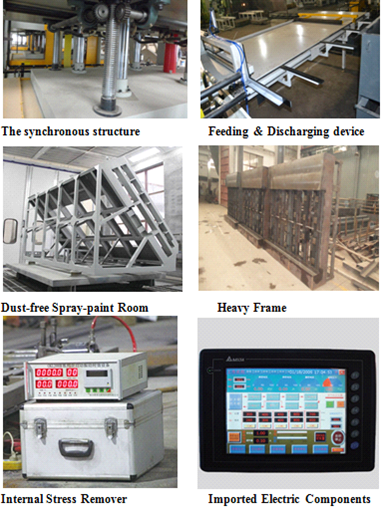

Our HF board jointing machine ( vertical lifting ) , which is the updated version of high frequency board jointing machine, with upper plate adopts vertical lifting and installs the synchronous system, so as to achieving higher planeness, saving 0.3mm plane thickness .

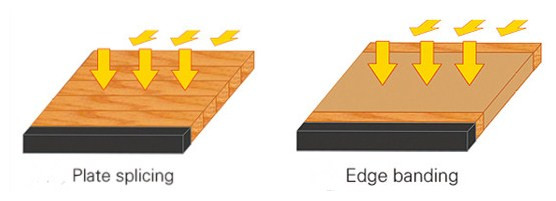

Application

It mainly apply to laminated wood, particle board, door panel jointing, and solid wood, door pocket, door line banding, or other wooden block gluing etc.

For Both short wood board and long boards .

Model Features

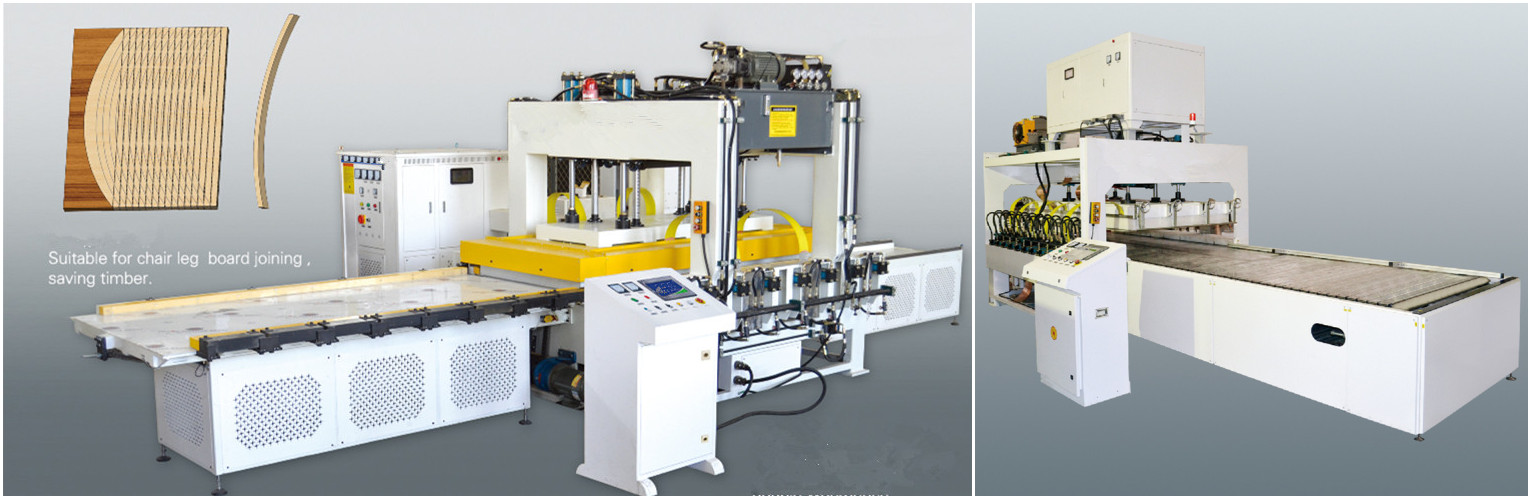

1. High Timber Outturn : 5%-10% more on average compared to the general clamp carrier

2. High Efficiency : 1-3 mins to finish one board , 15-20 seconds shorter than horizontal board joining , efficiency improved 5%-7%

3. Energy Saving : 15-30kw/h power consumption for 1cbm board jointing

4. Low Labor Cost : feeding & discharging device of belt-conveyer , adding palletizing and gluing system for option to get more efficient as well

5. Heavy Frame : Using large-scale machine tool to ensure its verticality

6. Easy Operation: Touch screen HML, with a built-in operation instruction which including installation, operation, repair, maintenance etc.

7. Safety : Adding high sensitive spark protection circuit and make separated cabinet for HF parts

8. Good components : assorting Taiwan pneumatic tools mostly

9. The thinnest board of jointing is 6mm at least

Model Details

Full cover for safty protection

Technical Parameters

| Platen size(mm) | 1300 ×5000 |

| Splicing thickness (mm) | 15-75 |

| Feeding mode | Crawler type , auto feeding , with 304 stainless steel chain |

| Up pressure(t) | 50 |

| Up cylinder specifications: | Φ63×400 |

| Up cylinder quantity (pcs) | 10 |

| Side pressure (t) | 100 |

| side cylinder specifications(mm) | Φ63×200 |

| side cylinder quantity(pcs.) | 20 |

| Hydraulic rated pressure(MPa) | 16 |

| Discharging mode | Auto discharging with stacking system |

| Heating mode | High frequency heating |

| HF power (KW) | 60 |

| Total input power(KVA) | 80 |

| Gluing way | one-components spraying glue applicator |

| Batten arranging system | With servo motor, position and distance between manipulators can be adjusted |

| Voltage | AC380V 50HZ 3Phase |

| Touching screen | human-machine interface |

| HF generator position : | On machine top |

| Total weight | 18000kg |

WorkShop

Case for referance

Optional device

—– Discharging pneumatic Transverse translation system

Functions

After high frequency splicing, the wooden slats are assembled into wooden boards, which are transmitted to the electric roller platform by chain plate transmission and electric roller relay. After reaching the position, the slats are pushed out horizontally by Transverse translation heads, and the height of board is adjusted through electrical automatic detection and control, then put the wood boards order on the lifting platform.

As a transition platform, the transverse translation system of the electric roller platform can be transferred to the hydraulic lifting platform after splicing multiple groups boards, effectively solving the discharge problem, and acheive the automation of logistics and production line, no forklift transfer and save cost .

Series Models

Double workbench HF board jointing machine & Crewle stype HF board jointing macine

Operation Video