Panel Rip Saw

Application of Panel Rip Saw

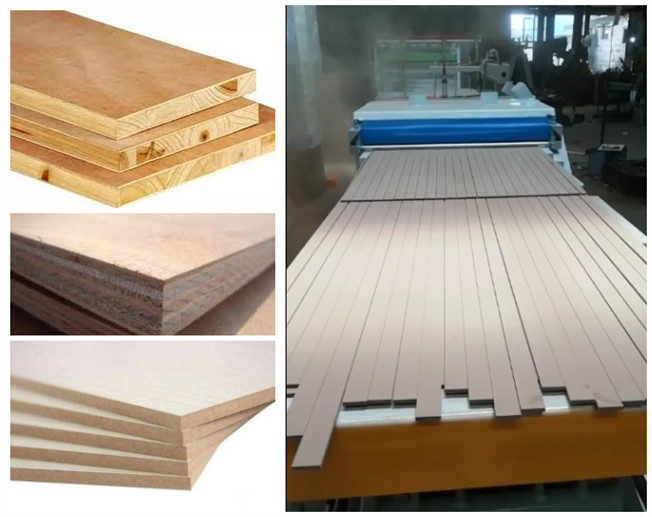

1. This panel rip saw with high performance and high precision,mainly used for wide sheet material, longitudinal sawing of square material, and can be sawed into multiple pieces of equal or different specifications in one time according to the pre-adjusted size. It can be used for density board, particleboard, wood-based panel,Solid wood composite flooring, laminate flooring, panel furniture, laminated timber, photo frame etc.

2. It can saw one plate into several parts in same or different specifications, or is used for grooving on surfaces of boards,It is an ideal high-efficiency equipment for construction, furniture, wood processing and other industries.

3. With a fast speed, saving labor more than 3 times, saving electricity by 70 %, greatly improving the production efficiency, expanding the profit space,producing products that are clean and tidy, without indentation, and without injury materials. Improve market competitiveness.

Our Panel rip saw Advantage

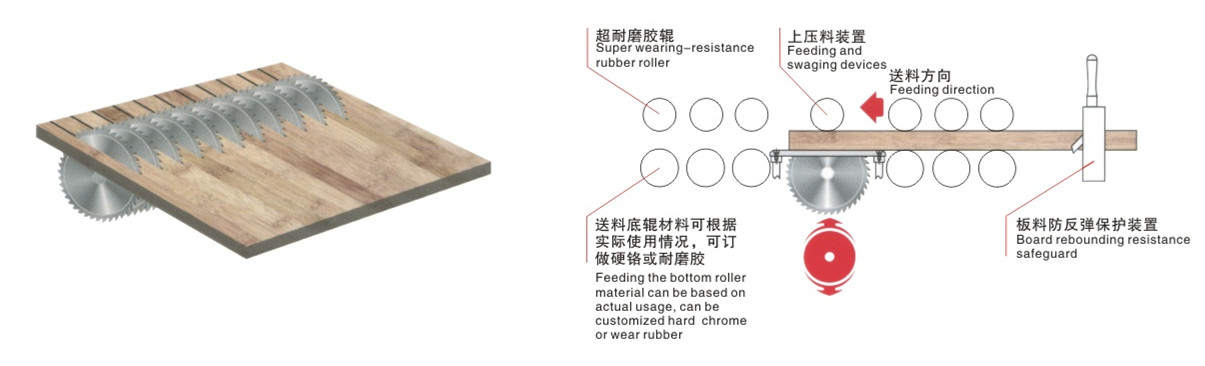

1.The spindle is bottom saw with lifting and a fully enclosed protective cover;the digital or manual lifting of spindle and upper pressing frame can be optioned. Strenghthened type spindle and axle bed. Anti-bouncing protector for plate is available.

2.The precision saw shaft ensures the smoothness and straightness of the cutting plate, and can be customized according to the customer’s individual requirements.

3.It is provided with a spindle at lower part and a fully-enclosed protective cover, and realizes manual lifting of spindle and pressing frame.

4. Precision saw spindle can make sure the sawed plates are more accurate in finish and straightness.

5. Dust protection and environmental protection device.

6. Using high quality alloy wear-resistant saw blade.

7. Intelligent integrated power distribution system, easy to operate, safe and stable.

8. All spacers has been processed with exquisite craftsmanship and special anti-rust treatment on the surface to ensure the stability and sawing plate size during high-speed operation.

| Model No.: | MJ1300-XD5 |

| Max working width: | 1300mm |

| Working thickness: | 0-50mm |

| Min. working length: | 650mm |

| Main spindle motor power : | 30KW |

| Main spindle is down saw, manual lifting | |

| Feeding motor power : | 2.2KW |

| Feeding speed : 0-12m/min | 0-12m/min |

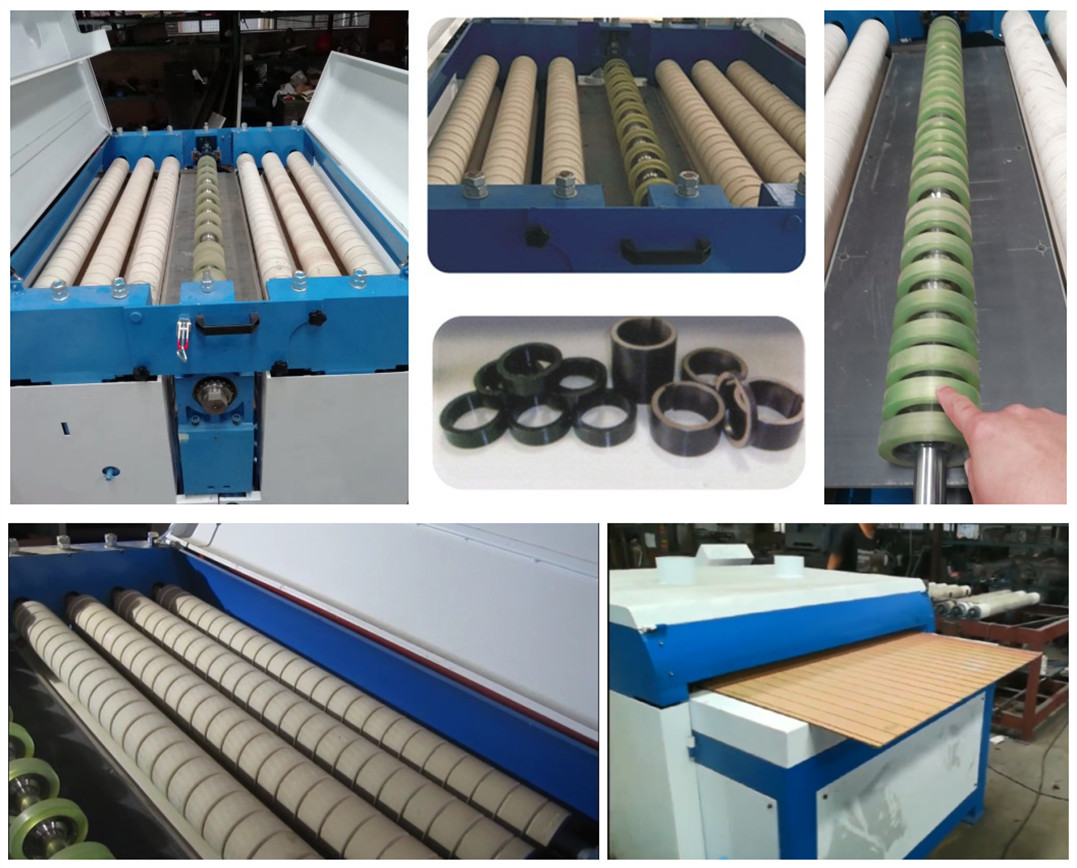

| Wearable roller: | 7 groups |

| 4 groups on front + 3 groups on back | |

| Rollers are manual lifting | |

Model Details

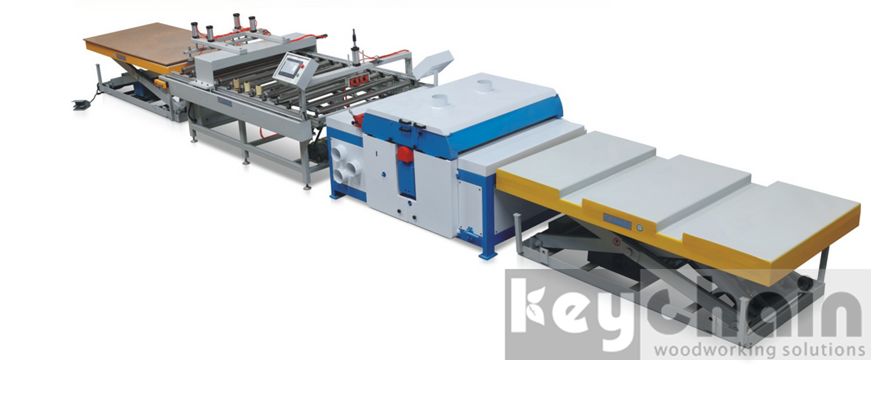

Automatic Production line

Operation Video